? ? 2022 Copyright ? Youibot Robotics Co., Ltd. All rights reserved.SitemapPrivacy Policy

Enhanced Efficiency

High Cleanliness

Full-site Scheduling

YOUIBOT’s robotics solution leverages high-precision composite mobile robots to efficiently handle materials like FOUP/FOSB, SMIF POD, cassettes, and magazines, enhancing production efficiency, quality consistency, and cost-effectiveness.

Aiming at the problems of inefficiency, human error and contamination risk in the internal logistics of the semiconductor industry, Youibot proposes the autonomous mobile robot (AMR) solution. Our material handling robots and mobile manipulators aim to connect the material flow and information flow between different processes, realizing automatic wafer transfer or automatic loading and unloading of materials in every workshop and manufacturing equipment. It dramatically improves semiconductor production efficiency and realizes seamless human-robot collaboration through the joint operation of mobile cobots, such as automated material handling robots and mobile robotic platforms with robotic arms.

As an industry-leading collaborative robotics company, we continue to explore the latest robot technologies, accumulate a wealth of successful cases, and build material handling robots that are widely recognized. These semiconductor composite robots can solve the problems of low efficiency and low product yield caused by manual operation.

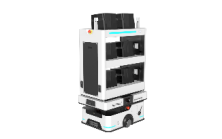

The O series of collaborative robots are custom designed for vaious materials handling scenarios in the semiconductor industry.

Due to smooth and contamination-resistant surfaces, the semiconductor robot meets a high cleanliness level. It minimizes human intervention, thus reducing the risk of contamination and increasing the product yield rate.

Autonomous mobile robots can run uninterruptedly for a set period of time. It enables automatic transfer or automatic loading and unloading of materials and intelligently navigates through complex environments without the need for human intervention or fixed tracks. This ensures a smooth production process to increase capacity.

The autonomous mobile robot, equipped with advanced vision sensors and an end gripper with strong control, grasps the FOUP PODs precisely, reducing direct contact with the wafers and minimizing vibration effects on the raw material.

Automated handling replaces some of the labor requirements. It not only reduces long-term labor expenses but also greatly avoids manual errors. Such cost reductions and efficiency enhancements help to realize a quick return on investment.

The integrated autonomous robot control system seamlessly integrates the robot's upper system and various end-sensing control systems into the internal operating system, reducing the cost and time of switching between multiple systems during deployment. Workflow and logging make all operations traceable and reduce management hassles.

The autonomous mobile robot's built-in SLAM algorithms help it locate its position and direction on a map to create a logical route of movement. It can also safely avoid obstacles in complex environments to safeguard personnel and equipment.

By continuing to use the site you agree to our privacy policy Terms and Conditions.